This story originally appeared on BUILDINGS.com

Choosing the Right Deicer for Your Indoor Carpeting?

Chloride-based deicers and anti-icers pose a threat to the environment, to pets and to humans, but you may be wondering why that matters when children and pets don’t typically walk or play on building walkways and stairways?

BY: NATE CLEMMER

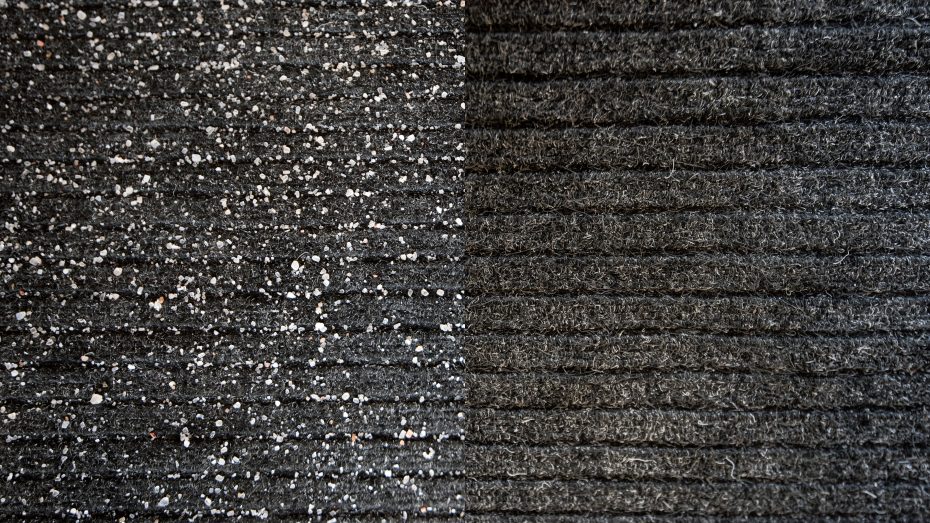

(Photo: An application of a liquid ice melt product.)

In addition, most of the surrounding surfaces that must be treated – driveways and parking lots – are areas where the potential for causing harm to children is minimal, and to pets almost non-existent.

However, sodium, calcium, potassium and magnesium chlorides are also causing damage in an entirely different location: inside the building on carpeting and flooring.

Deicers Damage Floors and Carpets

When tracked into a facility, some chloride deicers leave a white residue that can dull the finish of floors and fade the color of carpets.

Other chloride-based products coat floors with an oily residue that damages wax and urethane finishes. In both cases, the near-term labor costs associated with manual clean-up of residue is roughly $50 per building entrance per day, according to estimates by the Sanitary Supply Association’s Clean Management Institute.

Over time, chloride-based products can permanently damage flooring and carpeting, requiring expensive replacement. And then there’s the safety risk that the oily, slippery residue can pose to a building’s employees and visitors.

An alternative to these granular deicing materials are liquid deicers. One such product based upon potassium formate technology is 100 percent chloride free and it eliminates tracking, leaving no residue.

Potassium formate deicers also provide three benefits outside the building:

- Environmental friendliness

- Ease of application

- Product performance

Environmental Friendliness

Some chloride-based products can burn human skin when contacted. If inhaled, dust particles can cause severe irritation. If ingested, they can cause severe irritation and bouts of vomiting and diarrhea.

When cats and dogs walk on surfaces treated with some chloride-based products, they often experience painful burning, inflammation and cracked pads. If they lick their paws and ingest the salt, they may experience symptoms including excessive thirst, vomiting and diarrhea. Some chloride-based deicers are poisonous to pets.

When most chloride salts spread from sidewalks and driveways into nearby soil, they can have a defoliating effect on trees and other plants, and they interfere with plants’ ability to absorb vital nutrients including water, potassium, calcium and magnesium.

Potassium formate products, on the other hand, are readily biodegradable. They are safer for people, pets, plants, metal, concrete and other surfaces. In fact, their toxicity rate is significantly lower than that of chloride-based products and potassium acetate.

Ease of Application

Ease and speed of application combined with reduced transport and loading costs make liquids extremely attractive from a labor perspective.

Granular products can be very labor intensive, slowing the application process and negatively impacting safety in high-traffic pedestrian areas. For example, on stairs, applicators have to carry heavy bags, spreading material by hand, and in larger areas and walkways, push spreaders are often utilized. Liquid applications are far more efficient.

Liquid tanks fill quickly, and today’s spray applicator technologies are convenient and easy to use, providing for very precise application rates.

Product Performance

Potassium formate deicers create a safer environment more quickly than chloride-based deicers. For example, some potassium formate products have a speed of melt of about 30-50 seconds by reducing the freezing point to temperatures as low as -63 degrees F. These deicers quickly and reliably remove thin layers of ice and prevent new snow and ice from accumulating.

By contrast, chloride-based granular deicers take a minimum of 3-5 minutes to achieve an acceptable melt – and as much as 10 minutes.

The low quantity of liquid required to produce an adequate melt combined with the ease and speed of application makes most liquid deicers more cost-effective than granular products.

Most users will achieve a lower application cost per 1,000 square feet with liquids than with granular deicers. And because the liquid achieves ice melt three times more quickly than granular products, it creates a longer-lasting and safer walking surface.

The chemical reaction of chloride ice-melting solutions mixed with carpet cleaners creates white crystalline residue on carpets and matting.

The chemical reaction of chloride ice-melting solutions mixed with carpet cleaners creates white crystalline residue on carpets and matting. Once melted, the indoor tracking residue poses risks to human safety, creating opportunities for slip-and-fall accidents.

Once melted, the indoor tracking residue poses risks to human safety, creating opportunities for slip-and-fall accidents.